Counter Flow Technology (CFT)

Counter Flow Technology (CFT) water quality unit, is a cost-effective and eco-friendly structural BMP designed to meet the permit requirements of the NPDES Phase II program by treating the “first flush” of a given storm event. Lane’s CFT provides a mechanism to intercept stormwater flow, remove pollutants, and re-introduce treated flow in a manner suitable for today’s stormwater regulators. Lane’s CFT is manufactured from high-quality corrugated HDPE pipe and has no mechanical, moving or replacement parts, is less costly, more reliable and offers better efficiency than comparable products.

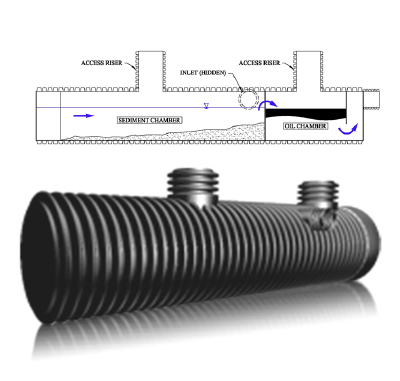

By incorporating weir and dividing plates into Lane’s larger diameter corrugated HDPE pipes the CFT attains the efficiency of larger more costly units by re-directing and lengthening the flow travel path to achieve slower velocities and increased settling times. A final chamber removes hydrocarbons and floatable debris before allowing flow back into the storm drainage system.

LANE has incorporated weir and dividing plates into their larger diameter corrugated HDPE pipes to create chambers conducive to directing and reducing flow velocity. Unlike many of today’s emerging water quality units, Lane’s Counter Flow Technology attains the efficiency of larger and more costly units by re-directing and lengthening the flow travel path to achieve slower velocities and increased settling times. The final chamber allows for the removal of hydrocarbons and floatable debris before routing flow back into the storm drainage system at a restricted rate.

The Lane CFT consists of a 20' or 40' mainline segment of 36”, 42”, 48” or 60” corrugated HDPE, along with inlet, outlet and bypass lines. Flow entering the mainline segment of the CFT is immediately re-directed via a full height plate that bisects the unit longitudinally. Flow is again re-directed at the extremity of the unit before being routed through the sediment chamber and under an oil baffle prior to discharging through an orifice outlet.